Uncover the Potential of Stepper Motors in Robotics

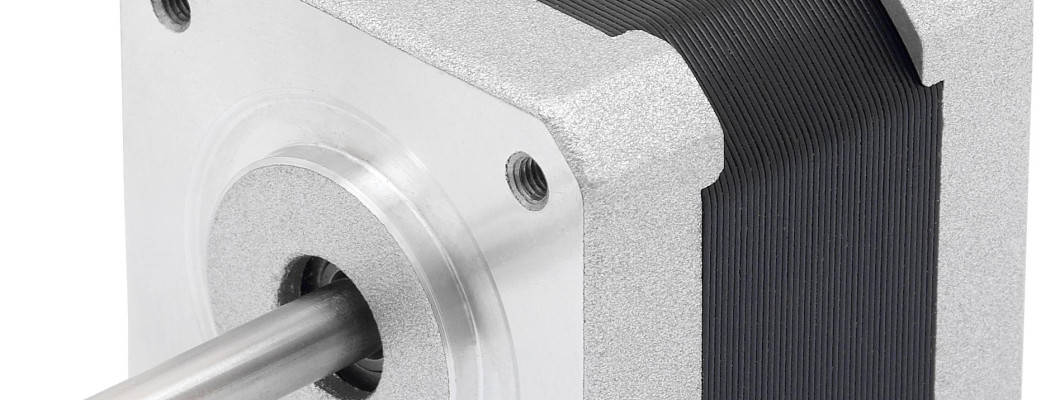

Introduction to Stepper Motors

Stepper motors are electromagnetic devices widely used in various industries and applications. Unlike other types of motors, they move in discrete steps, providing precise control over positioning. This blog post will delve into the advantages of stepper motors and explore their applications in robotics, 3D printing, and CNC machines.

Advantages of Stepper Motors:

Accurate Position Control:

Stepper motors excel at precise positioning, making them ideal for applications requiring accurate movements, such as robotics and CNC machines. Each step corresponds to a fixed angular displacement, allowing for precise control.

High Torque at Low Speeds:

Stepper motors offer high torque even at low speeds, enabling them to drive heavy loads efficiently. This characteristic makes them suitable for applications that require substantial force, such as 3D printers and linear actuators.

Open-Loop Operation:

Stepper motors operate in an open-loop system, eliminating the need for additional feedback devices. This simplifies the control system and reduces overall costs.

Cost-Effective Solution:

Compared to other motor types, stepper motors are relatively affordable. They offer excellent performance at a lower price point, making them a cost-effective choice for many applications.

Easy to Control and Program:

Stepper motors are easy to control and program, making them accessible to both beginners and experienced users. They can be easily integrated with microcontrollers and programmed to perform precise movements or complex motion sequences.

Applications of Stepper Motors:

Robotics and Automation:

Stepper motors power robotic systems, allowing precise control of joints and movements. They find applications in robotic arms, pick-and-place machines, automated guided vehicles (AGVs), and more.

CNC Machines:

Stepper motors are extensively used in computer numerical control (CNC) machines for precise positioning of the cutting tools. They enable accurate and repeatable movements required for machining operations.

3D Printers:

Stepper motors play a crucial role in 3D printers, controlling the movement of the print head and the positioning of the build platform. Their ability to provide precise control ensures accurate layer-by-layer printing.

Medical Equipment:

Stepper motors are employed in various medical equipment, such as diagnostic devices, robotic surgery systems, and prosthetics. Their precise control allows for accurate and reliable operations.

Camera Systems:

Stepper motors are used in camera systems to control focus, zoom, and aperture settings. They ensure precise adjustments for capturing high-quality images and videos.

Automotive Industry:

Stepper motors are utilized in automotive applications, including headlight leveling systems, HVAC actuators, and throttle control. Their precise positioning and high torque capabilities are crucial for these functions.

Stepper Motor Control:

Microstepping: Microstepping is a technique used to achieve smoother motion and finer resolution in stepper motors. It divides each full step into smaller increments, reducing vibrations and improving overall performance.

Half-Step and Full-Step Modes: Stepper motors can operate in either half-step or full-step modes. In half-step mode, the motor moves in smaller increments, providing higher resolution. Full-step mode offers more torque but lower resolution.

Drive Circuits and Controllers: Stepper motors require drive circuits and controllers to operate efficiently. These circuits convert electrical signals into the required current and voltage levels to drive the motor coils accurately.

Programming Considerations: Programming stepper motors involves sending the appropriate signals to the drive circuit or microcontroller. Understanding the motor's steps per revolution and the desired motion profile is essential for accurate control.

Types of Stepper Motors:

Permanent Magnet (PM) Stepper Motors: PM stepper motors have a permanent magnet rotor and are known for their high torque-to-inertia ratio. They offer good speed control and are commonly used in applications requiring high torque at low speeds.

Hybrid Stepper Motors: Hybrid stepper motors combine the features of PM and variable reluctance (VR) stepper motors. They provide excellent holding torque, smooth operation, and are widely used in a variety of applications.

Variable Reluctance (VR) Stepper Motors: VR stepper motors have a toothed rotor and rely on the principle of magnetic reluctance to generate motion. They are typically used in applications where cost is a primary concern.

Conclusion:

Stepper motors are versatile devices that offer precise positioning, high torque, and cost-effective solutions for various applications. Understanding their advantages, applications, control techniques, and types can help in selecting the right motor for specific needs.

Leave a Comment