Gear parts are used when large gear reductions are needed. It is common for Gear parts to have reductions of 20:1, and even up to 300:1 or greater.

Many Gear parts have an interesting property that no other gear set has: the worm can easily turn the gear, but the gear cannot turn the worm. This is because the angle on the worm is so shallow that when the gear tries to spin it, the friction between the gear and the worm holds the worm in place.

This feature is useful for machines such as conveyor systems, in which the locking feature can act as a brake for the conveyor when the motor is not turning. One other very interesting usage of Gear parts is in the Torsen differential , which is used on some high-performance cars and trucks.

Gear parts are special gears used in rudders, automobile steering mechanisms, hoists and rolling mills.

A Gear part drive consists of two elements:

Driving element ? Screw

Driven element ? Helical gear

Driving element (screw) is called worm and driven element (helical gear) is called Gear part or worm wheel.

Gear part drives are typically used for transmission of power between two non-parallel and non-intersecting shafts.

Advantages of Worm Drives:

- Gear part drives operate silently and smoothly.

- They are self-locking.

- They occupy less space.

- They have good meshing effectiveness.

- They can be used for reducing speed and increasing torque.

- High velocity ratio of the order of 100 can be obtained in a single step.

Applications of Gear part Drives:

- Worm drives are used in:

- Gate control mechanisms

- Hoisting machines

- Automobile steering mechanisms

- Lifts

- Conveyors

- Presses

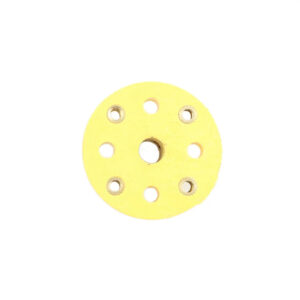

Specifications:

1 )Pitch Diameter=15 mm.

2) Length=22mm.

3) Center Shaft Diameter=6mm.